What exactly is plasma, and what is plasma physics?

After solids, liquids, and gases, plasma is frequently referred to as the fourth state of matter. It is an ionized gas composed of positively and negatively charged ions, electrons, and neutral atoms. Plasma physics is the study of plasma behavior and interactions with electromagnetic fields and other plasmas. Plasma physics has a wide range of applications, including energy generation, space exploration, and medicine.

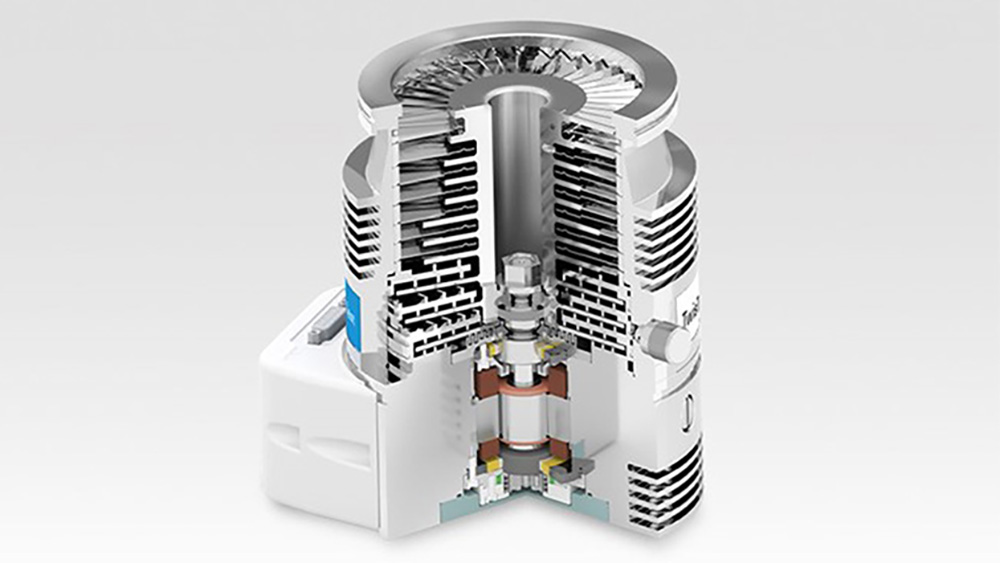

Vacuum technology is essential for understanding plasma physics, as it is used in both the study and creation of plasma. Vacuum chambers are used to create a vacuum environment with a low number of gas molecules so that plasma and particle beams can be generated and run in an ultraclean, hydrocarbon-free environment. High magnetic fields and radiation are both present in this environment.

The use of vacuum chambers allows researchers to study plasma behavior in a controlled environment, leading to a better understanding of plasma physics and potential applications.

Many practical applications of plasma physics can be found in fields such as medicine, energy, and materials science. Plasma physics has applications such as the generation of energy through fusion reactions, the creation of advanced materials, and the development of plasma-based propulsion systems for spacecraft.

Managing gases in a vacuum environment is one of the most difficult challenges in particle and plasma physics. In order to generate and operate a particle beam in an ultraclean, hydrocarbon-free environment, hydrogen and noble gases must be carefully controlled. This environment also contains high magnetic fields, posing additional challenges to researchers. To meet these challenges, specialized equipment such as ion pumps, dry scroll pumps, and magnetic field-resistant turbomolecular pumps are used to create and maintain a vacuum environment.

Choosing the right pumping technology is crucial when designing an ultrahigh vacuum (UHV) system for particle and plasma physics experiments. Because the pressure in a UHV system is typically less than 10-9 Torr, even a trace amount of gas can affect the quality of experimental results.

Agilent Vacuum Technology offers a range of pumping technologies for UHV systems, including ion pumps, turbomolecular pumps, and dry scroll pumps. Each of these technologies has its own strengths and weaknesses, and the choice of pump is determined by factors such as the required vacuum level, the type of gas being pumped, and the cost of the system.

Agilent’s solutions for particle and plasma physics applications include ion pumps, which are ideal for managing light and noble gases and quickly reaching ultra-high vacuum conditions, and dry scroll pumps, which offer quick chamber pump-down times. Agilent’s vacuum measurement systems, which use ionization and hot cathode technology, provide precise and dependable vacuum measurements. Furthermore, Agilent’s helium leak detectors ensure vacuum tightness, giving researchers peace of mind that their experiments will go as planned.

Agilent ion pumps are the ideal solution for particle and plasma physics experiments. They have no moving parts and thus produce no vibration or electrical noise, making them ideal for use in sensitive experiments. They are also made of radiation-resistant materials and can be baked out and regenerated, requiring little to no maintenance. Ion pumps can handle light and noble gases while quickly reaching ultra-high vacuum conditions, making them an essential component of any particle or plasma physics experiment.

To summarize, vacuum is an important aspect of plasma physics research, and managing gases in a vacuum environment is one of the most difficult challenges that researchers in this field face. Agilent’s vacuum solutions, which include ion pumps, dry scroll pumps, and turbomolecular pumps, can assist researchers in creating and maintaining an optimal vacuum environment for their experiments. Researchers can improve the quality and reliability of their experimental results by using the appropriate pumping technology and high-quality vacuum components.