When Mark’s father was admitted to the hospital after a stroke, the family didn’t think much about the mattress he was lying on. It looked ordinary enough—until they noticed it was quietly moving him from side to side every few minutes, adjusting pressure points, and somehow keeping him comfortable during weeks of immobility.

What they were seeing was the result of 30 years of engineering focused on solving one specific medical problem: how to prevent pressure injuries in patients who can’t move themselves. The automated lateral turning mattress had become so refined that it did its job almost invisibly.

The Problem That Drove Innovation

Pressure injuries develop when blood flow gets cut off to skin and tissue, usually because someone can’t shift their weight naturally. For patients recovering from strokes, spinal injuries, or major surgeries, this becomes a serious medical issue that can complicate recovery and extend hospital stays.

Traditional prevention relied on nurses manually turning patients every couple of hours. But hospitals are unpredictable places—emergencies happen, staff get pulled away, and sometimes those crucial repositioning schedules get missed.

ABeWER started working on this challenge in the early 1990s, when automated solutions were clunky, loud, and often created more problems than they solved. The goal was simple: build a mattress that could do what healthy bodies do naturally during sleep.

Three Systems Working as One

The multiTURN® 6 combines three different approaches to pressure management. First, automatic lateral turning gently rocks patients from side to side, mimicking natural sleep movement. Second, alternating pressure technology cycles different air chambers to redistribute weight continuously. Third, continuous low pressure management maintains baseline comfort across the entire surface.

Getting these three systems to work together without interfering with each other took years of refinement. Early prototypes either moved too abruptly, made too much noise, or couldn’t coordinate the different functions smoothly.

Engineering for Real Healthcare Environments

Building automated turning mattresses that work in actual hospitals required solving problems you don’t encounter in laboratory testing. The systems had to operate quietly enough not to disrupt patient sleep—under 20 decibels—while running continuously for months.

They needed to work with different power systems, handle various patient weights and medical conditions, and remain simple enough for healthcare staff to operate during busy shifts. The materials had to withstand repeated cleaning with harsh hospital disinfectants while maintaining patient safety standards.

Patient Control and Independence

One crucial feature is the remote control that allows patients with upper body mobility to adjust their own positioning. This isn’t just about comfort—it’s about maintaining some independence during recovery when patients often feel completely helpless.

The engineering challenge was making controls that respond to patients with limited strength or dexterity while ensuring that adjustments happen smoothly and quietly. Every button press has to trigger gentle movement rather than abrupt changes that could disturb sleep or cause discomfort.

Built for Global Healthcare

The multiTURN® 6 technology now operates in healthcare facilities worldwide, from high-tech urban hospitals to rural care centers with limited infrastructure. This required engineering systems that work consistently regardless of electrical systems, environmental conditions, or maintenance capabilities.

The mattresses include customization options for different facility needs while maintaining the core functionality that makes them effective for pressure injury prevention. Size variations, design modifications, and additional features can be adapted without compromising safety or performance.

Reliability That Healthcare Providers Trust

ABeWER backs their automated turning mattresses with two-year warranties covering all components. In healthcare, equipment failure isn’t just an inconvenience—it directly affects patient care. The warranty reflects confidence that these systems will operate reliably under continuous use.

Customer support teams provide rapid response when issues arise, understanding that downtime affects vulnerable patients who depend on the technology for pressure injury prevention. This support infrastructure is as important as the initial engineering.

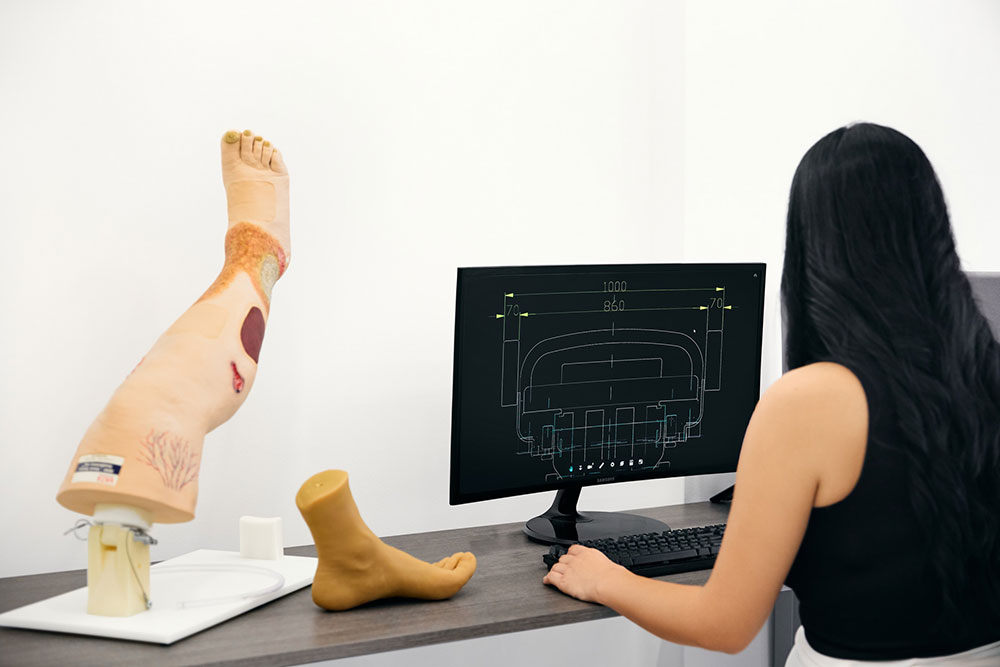

Materials and Manufacturing Precision

Creating breathable materials that provide patient comfort while housing complex mechanical systems required extensive testing and development. The materials have to maintain their properties through repeated sterilization cycles while dampening any vibration or noise from internal mechanisms.

Manufacturing precision ensures that every multiTURN® 6 performs consistently, whether it’s used in a quiet private room or a busy ICU environment. Quality control procedures verify that noise levels, pressure management, and turning functions meet specifications before systems ship.

CE Certification and Safety Standards

Getting CE certification for complex automated medical devices requires extensive documentation proving safety and effectiveness. The testing process covers everything from electrical safety to patient interface materials to long-term reliability under continuous operation.

This certification gives healthcare providers confidence that the technology meets rigorous European standards for medical devices. The process takes significant time and investment but ensures that patient safety remains the top priority.

Integration with Clinical Workflows

Successful medical technology has to enhance rather than complicate existing healthcare procedures. The multiTURN® 6 was designed to integrate seamlessly with standard patient care protocols while providing automated pressure management that doesn’t require constant nursing intervention.

Healthcare providers can focus on other aspects of patient care knowing that pressure injury prevention is being handled consistently and reliably. This integration allows the technology to improve outcomes without adding complexity to already demanding clinical environments.

Measuring Success in Patient Outcomes

The effectiveness of automated turning mattresses shows up in reduced pressure injury rates, improved patient comfort scores, and decreased nursing time spent on manual repositioning. Healthcare facilities report significant improvements in these metrics after implementing the technology.

But the real measure of success is individual patients like Mark’s father, who recovered from his stroke without developing pressure complications that could have extended his hospital stay or complicated his rehabilitation.

Future Developments in Automated Care

Recent analysis of advanced automated patient positioning systems shows how the field continues evolving. Current systems represent significant advancement over early automated turning technology, but ongoing development promises even better patient outcomes.

The focus remains on preventing complications before they develop rather than treating problems after they occur. Automated turning mattresses prove that sophisticated technology can improve healthcare outcomes while simplifying rather than complicating patient care.

The Long-Term Vision

Thirty years of focused development has created automated turning mattresses that quietly handle pressure injury prevention while patients focus on recovery. The technology works so seamlessly that families like Mark’s often don’t realize how sophisticated the engineering is until they see the results.

This represents the best kind of medical technology—solutions that improve patient outcomes while remaining virtually invisible to the people they’re helping. The multiTURN® 6 demonstrates how sustained engineering focus can create healthcare technology that genuinely makes a difference in patient care.